Navigating OSHA’s New National Emphasis Program on Heat-Related Illnesses

The Occupational Safety and Health Administration (OSHA) has introduced a groundbreaking National Emphasis Program (NEP) focusing on heat-related hazards, marking a significant shift in enforcing workplace safety standards related to heat exposure.

Understanding the NEP:

- Launch and Duration: This program, titled ‘Outdoor and Indoor Heat-Related Hazards’, began on April 8th, 2022, and is set to last three years, subject to cancellation or extension.

- Scope: The NEP targets 70 industries recognized as high-risk for heat-related illnesses, both in indoor and outdoor settings.

- Trigger for Inspections: Inspections will intensify when the National Weather Service issues heat warnings or advisories of 80°F or higher.

- Industries Covered: The program spans various industries, from the obvious ones like construction and farming to less apparent ones like office services, automobile dealerships, and restaurants. Even businesses with outdoor seating areas are included.

What is an OSHA Inspection Under This NEP?

- Process: An OSHA inspection involves an opening conference, a comprehensive walk-around of the jobsite, and a closing conference.

- Documentation Review: Inspectors will request and review essential documents such as OSHA Form 300, safety programs, training logs, SDS logs, and preventive maintenance records.

- Site Examination: The walk-around will focus on specific heat-related hazards but can expand to other observed safety issues.

- Employee Interviews: Inspectors may interview employees privately to understand their safety concerns.

Consequences of Violations:

- Citations: OSHA will issue citations for any violations found, with a six-month window post-inspection to do so. These citations focus on the employer’s responsibility to provide safe working conditions.

- Public Record: Citations and related information become public records, potentially affecting the company’s reputation.

Proactive Steps to Pass an Inspection:

- Prioritize Employee Safety: Reduce the likelihood of inspections by seriously addressing worker safety and well-being.

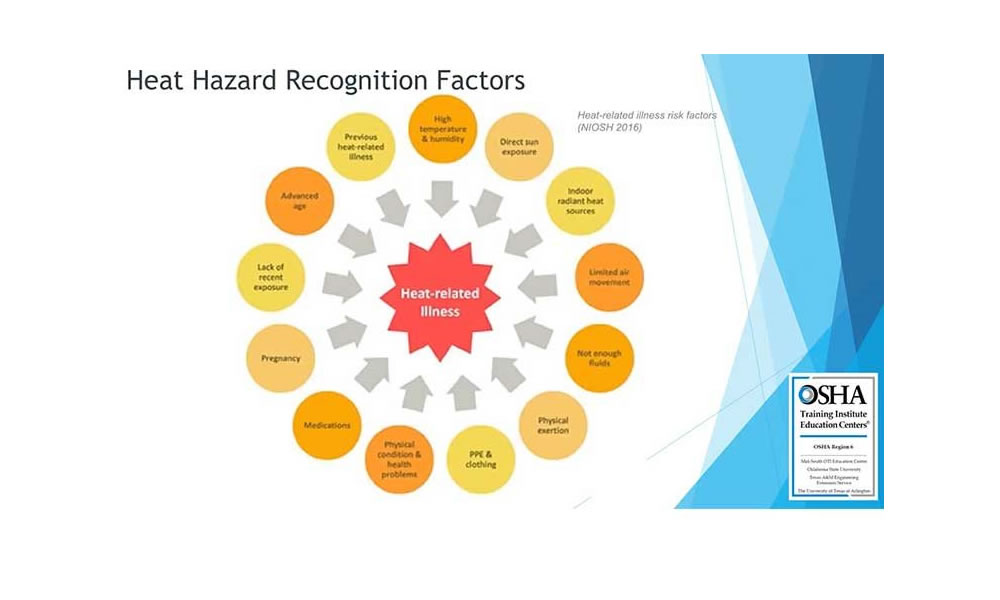

- Develop a Heat Stress Safety Program: Implement a comprehensive program covering all aspects of heat exposure and stress, including training.

- Ensure Overall Safety Compliance: Be prepared for a broader inspection scope by maintaining up-to-date safety programs and training in line with OSHA standards.

Seeking Professional Assistance:

- Evaluate In-house Resources: Determine if your company has the capacity and expertise to handle OSHA compliance.

- Consider Third-Party Services: For companies without dedicated safety officers, hiring professional safety consultants like Lancaster Safety Consulting Inc. can provide tailored programs and training.

- Real Work for Real Safety: Safety compliance is an ongoing effort requiring more than just template-based solutions.

Conclusion:

OSHA’s new NEP on heat-related hazards underscores the agency’s commitment to worker safety in evolving workplace environments. Understanding the nuances of this program and preparing accordingly is crucial for businesses to not only comply with regulations but also to reinforce their commitment to employee well-being.

For assistance in navigating these new requirements and ensuring compliance, businesses can reach out to professional safety consultants for specialized support and training.