Follow this 5-step Framework to Prevent Focus Four Accidents

In our commitment to ensuring every worker returns home safely each day, CCS Safety Solutions advocates for a comprehensive safety program that addresses all hazards, including OSHA’s Focus Four. Here are the essential steps:

- Conduct a Safety Evaluation: Start by identifying potential hazards through a thorough hazard assessment. This crucial step requires the collective knowledge of your team and may benefit from the expertise of third-party safety consultants like CCS Safety Solutions. Remember, safety is a collaborative effort!

- Implement Engineering Controls: Prioritize engineering controls to mitigate risks. These are physical modifications in the work environment to reduce or eliminate hazards, such as guardrails for fall prevention, barriers against vehicle or equipment accidents, and machinery guards to prevent caught-in/between incidents.

- Conduct Regular Inspections: Regularly inspect equipment and work areas to preemptively identify potential hazards. Ensure that all equipment is properly maintained and that workspaces are free of dangers.

- Train Workers: Empower your workforce with knowledge. Provide comprehensive training on potential job hazards and safe work practices, including the correct use of all equipment. CCS Safety Solutions offers flexible online or onsite OSHA training on numerous topics to facilitate this training.

- Provide Personal Protective Equipment (PPE): PPE is your last line of defense. Ensure you provide appropriate PPE, like fall protection harnesses, hard hats, and safety goggles, in compliance with OSHA mandates.

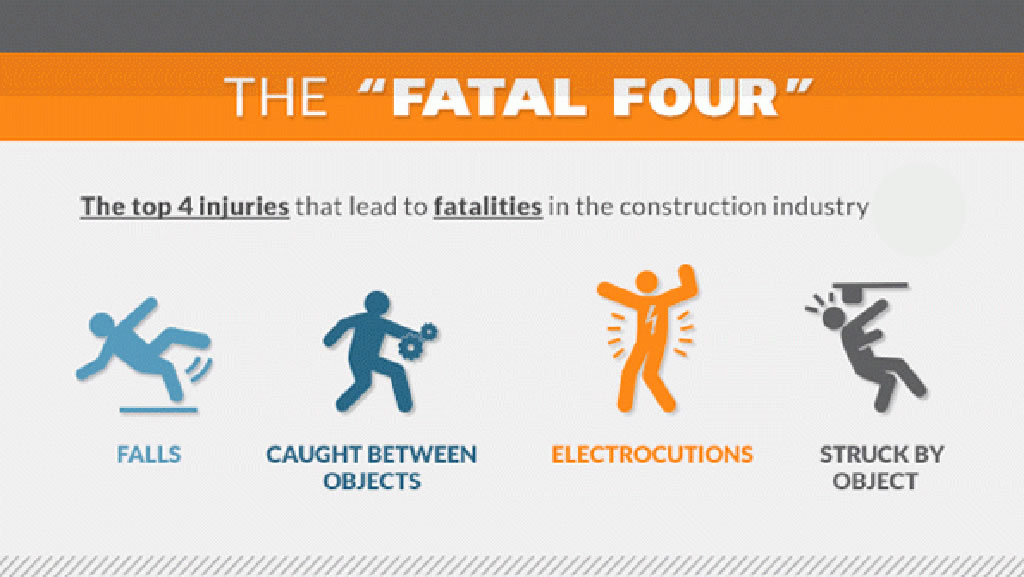

Detailed Actions to Prevent Each of the Focus Four Hazards:

- Falls: Utilize fall protection equipment, ensure structurally sound walking surfaces, train workers in fall protection equipment use, regularly inspect this equipment, use warning signs, and provide safe access to elevated areas.

- Electric Shock: Implement proper grounding procedures, provide electrical safety PPE, train workers in electrical safety, mark electrical hazards, and use appropriate cords and wiring.

- Struck-by Accidents: Employ barriers, avoid overloading equipment, maintain vehicles and equipment, provide high-visibility clothing, and train workers in traffic control and equipment operation.

- Caught-in/Between Accidents: Train workers in equipment use and safety procedures, implement lockout/tagout procedures, use proper guarding, provide adequate space around machinery, and ensure trench/excavation safety.

Four Action Items for Comprehensive Focus Four Accident Prevention:

- Assemble your safety team and assign responsibility for each action.

- Identify any expertise gaps in your team and consider consulting with safety experts like CCS Safety Solutions.

- Follow the 5-step framework to develop a robust written safety program:

- Hazard assessment

- Engineering controls

- Regular inspections

- Worker training

- PPE provision

- Establish a safety committee with members from all company levels and conduct regular meetings.

Need Help Getting Started?

If you lack a dedicated safety team, require training, or seek experienced safety consultancy, CCS Safety Solutions is here to assist. Our experienced professionals can provide the expertise needed to ensure your company’s safety. Contact us at 888-586-9495.